Introduction of the central laboratory

Principal of Central Laboratory of the Hamedan University of Technology: Instrumentation and setting up central laboratories and creating an infrastructure for applied basic research is one of the strategic goals of Hamedan University of Technology. According to the report of the university's public relations office, the central laboratory of Hamedan University of Technology has been set up in two levels A and B instruments since 2015. As an important center, this collection aims to meet the research needs of researchers at the university and provincial levels and at the national level.

Dr. Yousefi Seyf added: The central laboratory of Hamedan University of Technology in 2015 in line with the realization of the strategic document of the university approved on April 04, 2016, with the aim of providing research services not only to faculty members, researchers, and graduate students of the university but also to the researchers, industrialists, and institutions outside the university.

Among the other tasks of this laboratory, the objective is to concentrate and organize the advanced facilities and instruments needed by different majors, optimal efficiency of the existing facilities, saving the cost of projects, etc, Dr. Yousefi Seyf stated.

The central laboratory is divided into two levels of instruments, including A and B. Level A includes Hi-Tech instruments and Level B includes general laboratory instruments.

The central laboratory provides services to all universities, scientific and research institutions, various industries, and private sectors. Therefore, all public and legal persons can benefit from its services. Among the goals of this laboratory, the following can be mentioned: Establishing communication between laboratories inside and outside the university in order to provide mutual services, optimal use of the research capacity of faculty members, improving the educational and research quality of graduate students, improving the quality and variety of services to customers, and increasing compliance with the principles of safety, workplace health, and environmental regulations according to standards.

To download the manual of the central laboratory of the university, refer to this link.

Manager: Dr. Jaber Yousefi Seyf

Tel: +98 (81) 38411453

Email: Centrallab@hut.ac.ir

Education: Ph.D. in chemical engineering

Records: Director of the central laboratory

Principal of Central Laboratory of the Hamedan University of Technology: Instrumentation and setting up central laboratories and creating an infrastructure for applied basic research is one of the strategic goals of Hamedan University of Technology. According to the report of the university's public relations office, the central laboratory of Hamedan University of Technology has been set up in two levels A and B instruments since 2015. As an important center, this collection aims to meet the research needs of researchers at the university and provincial levels and at the national level.

Dr. Yousefi Seyf added: The central laboratory of Hamedan University of Technology in 2015 in line with the realization of the strategic document of the university approved on April 04, 2016, with the aim of providing research services not only to faculty members, researchers, and graduate students of the university but also to the researchers, industrialists, and institutions outside the university.

Among the other tasks of this laboratory, the objective is to concentrate and organize the advanced facilities and instruments needed by different majors, optimal efficiency of the existing facilities, saving the cost of projects, etc, Dr. Yousefi Seyf stated.

The central laboratory is divided into two levels of instruments, including A and B. Level A includes Hi-Tech instruments and Level B includes general laboratory instruments.

The central laboratory provides services to all universities, scientific and research institutions, various industries, and private sectors. Therefore, all public and legal persons can benefit from its services. Among the goals of this laboratory, the following can be mentioned: Establishing communication between laboratories inside and outside the university in order to provide mutual services, optimal use of the research capacity of faculty members, improving the educational and research quality of graduate students, improving the quality and variety of services to customers, and increasing compliance with the principles of safety, workplace health, and environmental regulations according to standards.

To download the manual of the central laboratory of the university, refer to this link.

Manager: Dr. Jaber Yousefi Seyf

Tel: +98 (81) 38411453

Email: Centrallab@hut.ac.ir

Education: Ph.D. in chemical engineering

Records: Director of the central laboratory

The central laboratory is divided into two levels of instruments, including A and B. Level A includes Hi-Tech instruments and Level B includes general laboratory instruments.

Level A instruments:

-

Gas chromatography (GC)

-

Atomic absorption spectroscopy (AAS)

-

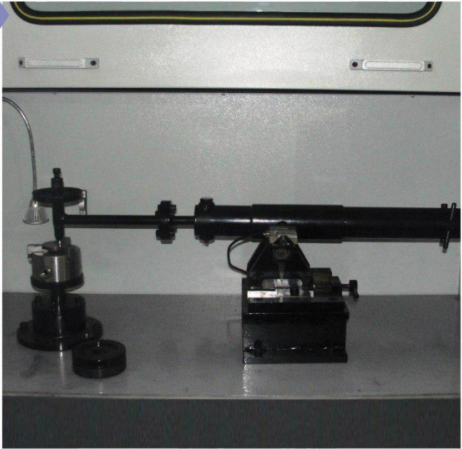

Vibrating sample magnetometer (VSM)

-

Thermogravimetric analysis (TGA)

-

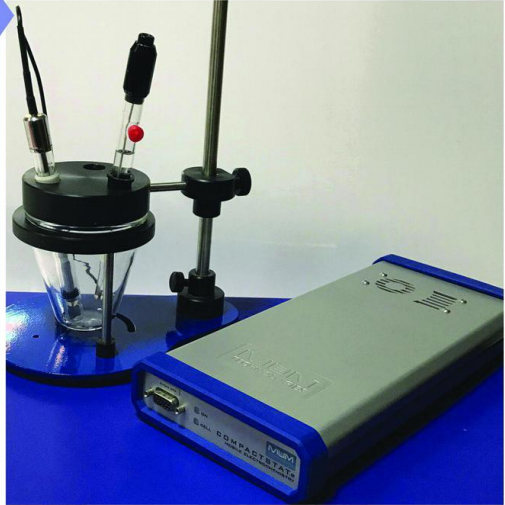

Electrochemical Characterization Set (Potentiostat)

-

Densitometer

-

Viscometer

-

Tensiometer

-

Abrasion test

-

Wirecut

-

Vickers microhardness

-

Universal testing machine (STM-250)

-

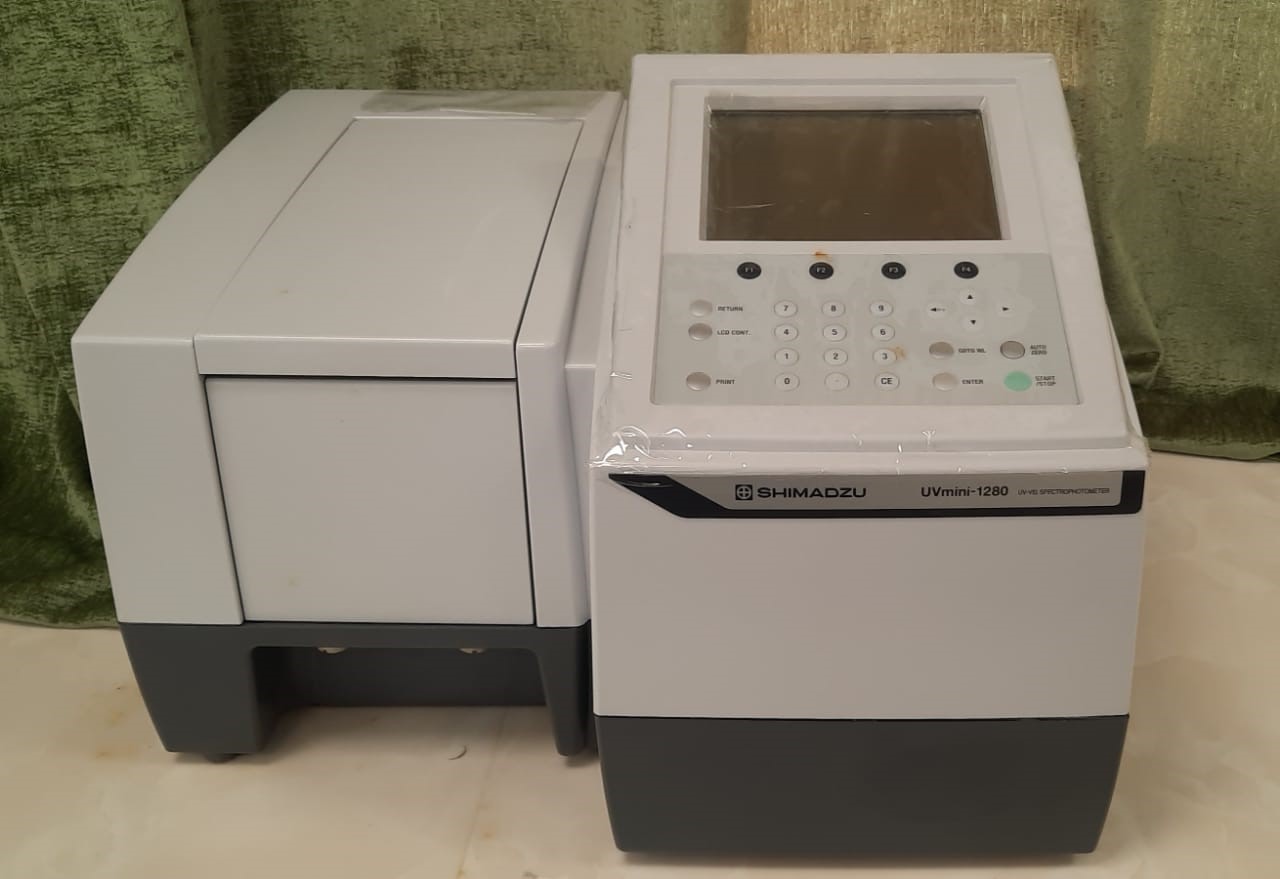

UV-Visible spectrophotometer

Level B instruments:

Level B instruments:

- Centrifuge

- Centrifuge T.16

- Distilled water deionizer

- Distilled water

- Incubator

- Ultrasonic homogenizer

- Vacuum oven

- Digital balance

- Hot plate magnet (heater stirrer)